Overview

The Item Location Maintenance module enables users to manage and optimise the physical and logical locations of inventory items.

Function

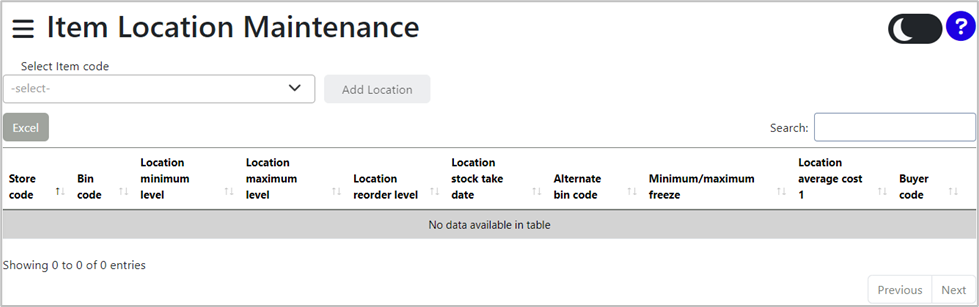

Once opened you will view the following screen:

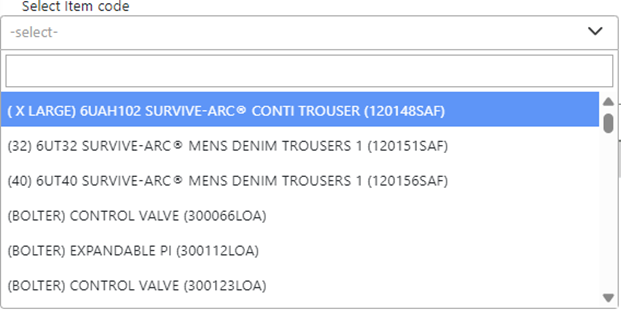

The item code can be selected from the drop-down menu ![]() under ‘Select Item Code’:

under ‘Select Item Code’:

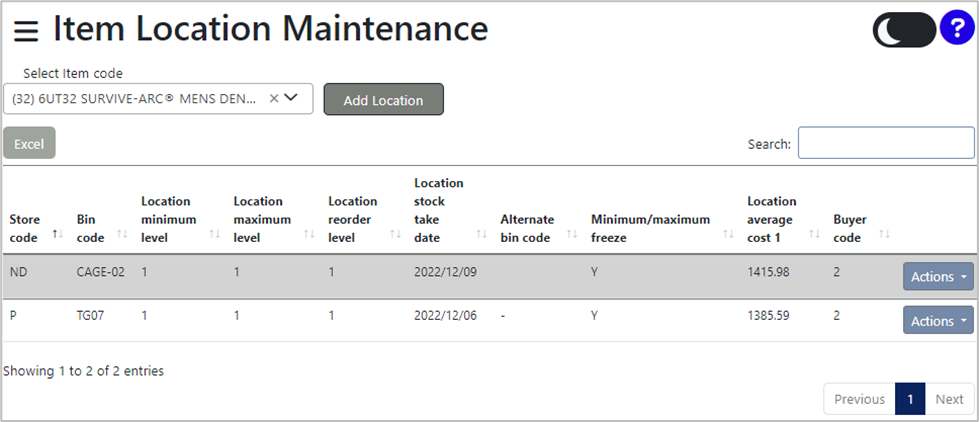

Selecting an item code will provide a list of items listed under the item code. The items will be listed as follows:

The list of items can be exported into MS Excel by selecting the ![]() button.

button.

Specific items can be searched using the search bar on the right-hand side of the screen.

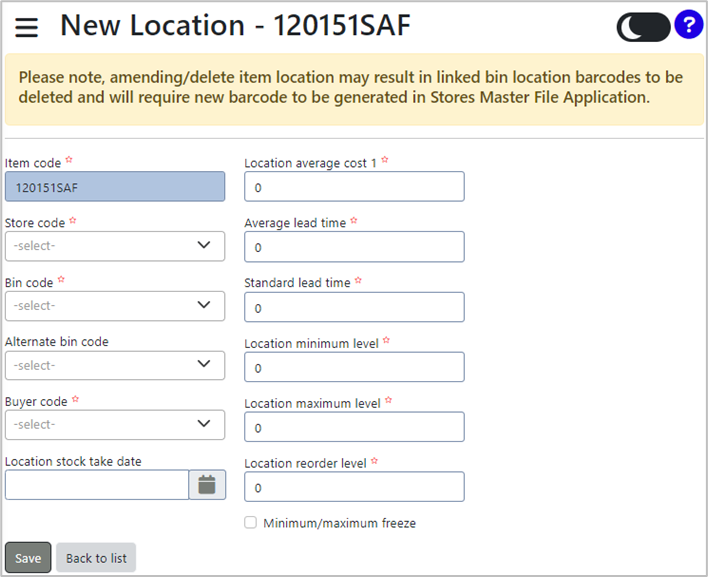

To add an item location, select the ![]() button. A new screen will be displayed:

button. A new screen will be displayed:

Complete the fields. Fields marked with an asterisk (*) are compulsory.

The item code will be automatically populated based on the selected item.

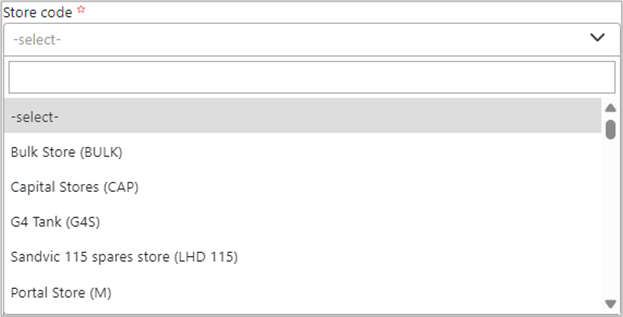

Select the Store Code from the drop-down menu:

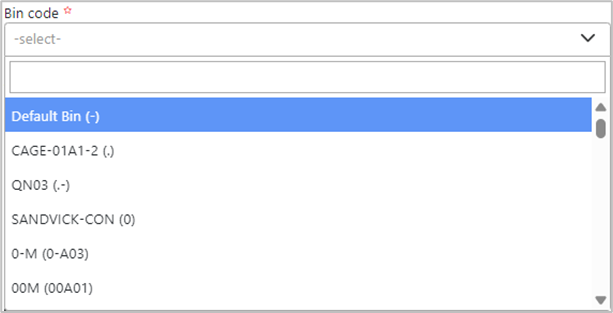

Select the Bin Code from the drop-down menu:

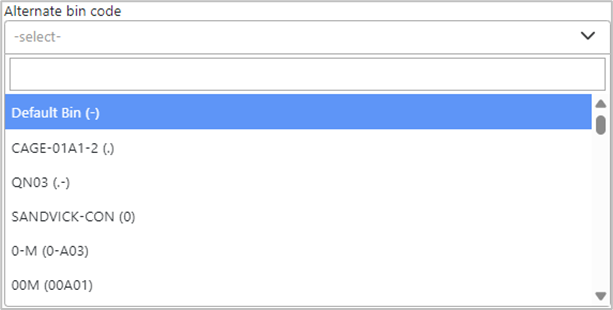

The Alternate Bin Code can be selected from the dropdown menu (optional).

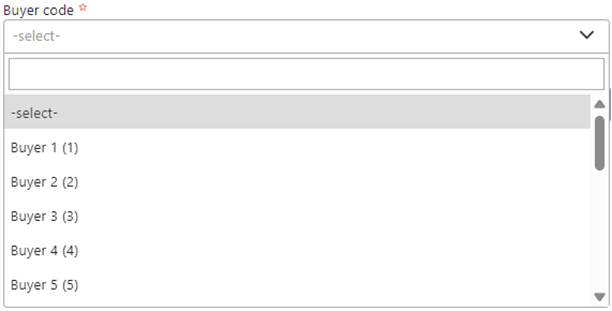

Select the Buyer Code from the drop-down menu:

Select the Location Stock Take Date by selecting the calendar icon ![]() .

.

Enter the Location Average Cost manually.

The following fields can be completed manually or adjusted using the up and down arrows:

•Average Lead Time: The typical amount of time, in days, that it takes for an item to be delivered after placing an order, based on historical data.

•Standard Lead Time: The expected or predefined time, in days, for the delivery of an item from the supplier, used for planning purposes.

•Location Minimum Level: The minimum quantity of an item that should be available at a specific location to prevent stock shortages.

•Location Maximum Level: The maximum quantity of an item allowed at a location to avoid overstocking and manage storage capacity efficiently.

•Location Reorder Level: The stock level at which a new order should be placed to replenish the item before it reaches the minimum level.

The Minimum/Maximum Freeze tickbox means that the values for the minimum and maximum stock levels at a specific location are "frozen" or locked. When this box is ticked, it prevents automatic updates or adjustments to the minimum and maximum stock levels, even if certain conditions or system rules would normally alter them.

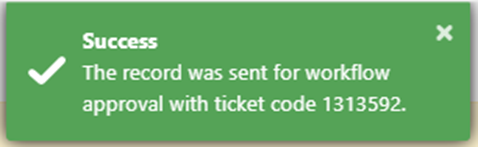

Once all the required information has been completed, select the ![]() button. A pop-up message will be displayed, confirming that the record has been sent for Workflow approval, including the ticket code number:

button. A pop-up message will be displayed, confirming that the record has been sent for Workflow approval, including the ticket code number:

The entry will now be visible on the Item Location Maintenance screen.